Sanitation

The need remains for a continuous means of sanitizing and disinfecting high-touch and other environmental surfaces where persistent microbial pathogens can be found

Read More

Keeping It Clean—Can Sanitizing Be More Sustainable?

When implementing water-saving initiatives or using more environmentally friendly chemicals, care must be taken to avoid compromising hygiene

Anette Granly Koch M.Sc., Ph.D.

Gry Carl Terrell M.Sc.

Freja Lea Lüthje

Rikke Hjort Hansen

Emma Bildsted Petersen

June 12, 2023

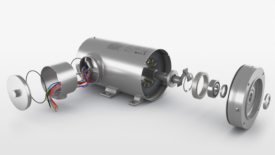

Designing for Greatness while Considering Total Cost of Ownership

The total cost of ownership, and not only the price tag, is critical to consider when evaluating the hygienic design of equipment

April 10, 2023

Never miss the latest news and trends driving the food safety industry

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing