Food Safety

How Processors Can Use Robots to Enhance Food Quality and Safety

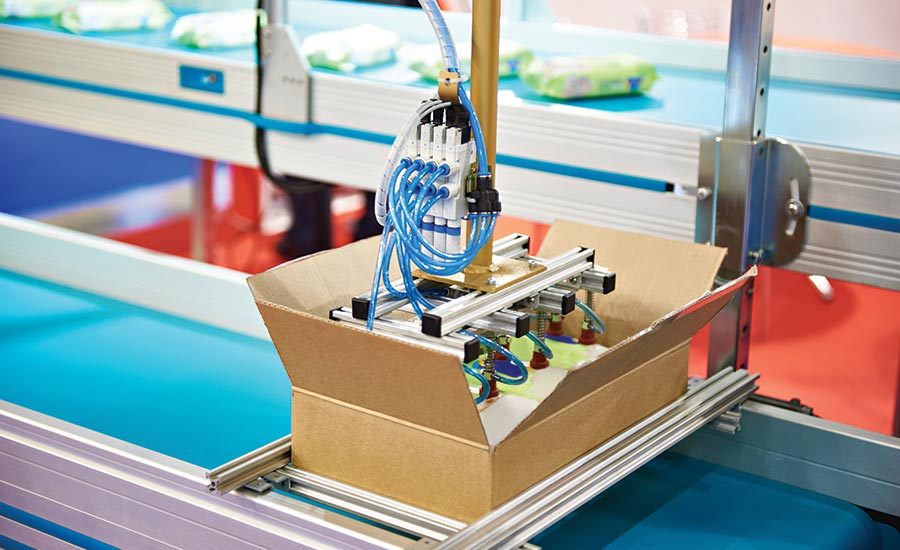

Packaging is one of the top jobs for robots in food factories, eliminating a repetitive task for humans.

Photo courtesy of Getty Images

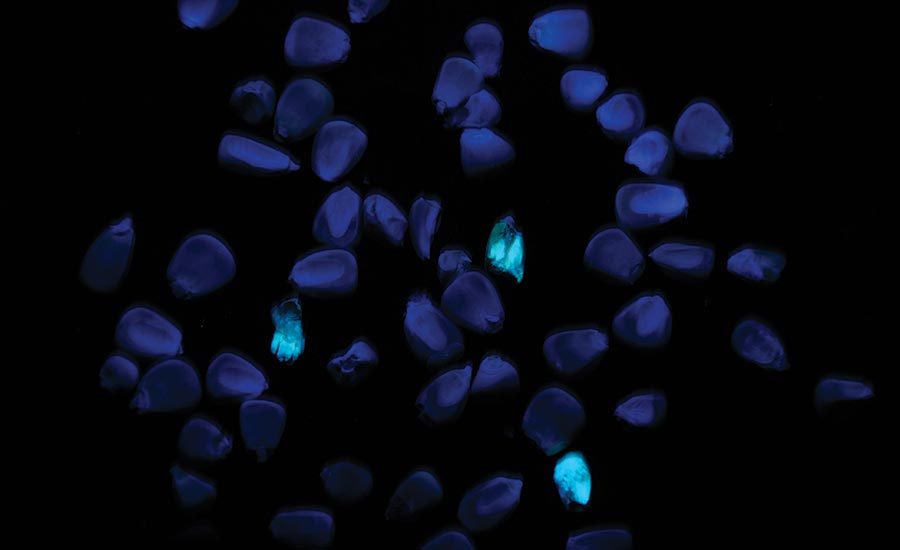

One of the best applications for robotics is sorting. Bühler created LumoVision to find and remove cancer-causing, aflatoxin- infected grains.

Photo courtesy of Bühler

One of the best applications for robotics is sorting. Bühler created LumoVision to find and remove cancer-causing, aflatoxin- infected grains.

Photo courtesy of Bühler

Decreasing human handling of food reduces risk of cross-contamination.

Photo courtesy of Getty Images

When most people think of robots, they tend to think of a metallic humanoid from science fiction.

But robots or robotics are more than humanoid creations. We can thank Isaac Asimov for the creation of the term robotics back in 1941:

The branch of technology that deals with the design, construction, operation and application of robots.

Specially built robotic machines have evolved to fill many niches. Any kind of machine automation may be deemed robotic. The question is: How are robots used in the food industry and what might the future hold for the industry?

There are many food processing operations where robots are applied:

- Receiving

- Warehousing

- Processing

- Quality

- Casing and packing

- Shipping

- Sanitation

- Sampling and testing

Let’s follow the process flow from field to consumer to look at how robotics may be applied to food production, processing and handling.

Agriculture

Robotics are used for two basic agricultural applications: growing and harvesting. Some farmers are now employing robotics sensors to monitor different variables essential to efficient food production. The sensors may be used to monitor such parameters as soil moisture, soil acidity and temperature. With more and more farmers adopting drip irrigation technology, the sensors may be linked to the system to deliver water and nutrients as needed. These systems are designed to ensure more efficient operations.

Growers have utilized mechanical harvesting systems for many, many years. This could be considered a robotics application. Mechanical harvesters have certain drawbacks in that they may collect nonfood items. I have personally seen some of the foreign materials that come in with mechanically harvested products, including snakes, glass, metal, stones and many others. Processors purchasing mechanically harvested material must install systems, such as air blowers, float tanks and magnets, to catch contaminates.

Food processing applications

Robotics advocates like to talk about potential advantages of using robots in food processing applications. They mention that robots can work in harsh environments that would be uncomfortable for humans, that robots are sanitary and can be “sterilized” (which is the wrong word) and can work more safety. These advantages are all true, except for the comment about sterility. Any robotic system that touches foods needs to be designed so that it can be properly cleaned and sanitized. The 10 principles of sanitary design established by the American Meat Institute must be applied to any equipment manufactured for use in food processing.

Among the current applications for robotics in food processing are meat processing, sorting, food handling (especially fruits, vegetables and leafy greens), and very specific applications, such as cake decorating. Meat processing is an interesting application in that meat is extremely variable in size, shapes, marbling and fat distribution. The meat application, therefore, focuses on beef carcass butchering rather than preparing cuts for retail sales. The driving force in this application is in part worker safety. The human effort involved in butchering carcasses is considerable, and the tools needed are potentially hazardous. Butchers work in a cold environment and must wear the appropriate garments to keep warm and essential personal protective equipment to protect themselves from injury.

Another potential application for robotics involves gripping and moving or placing different food products. Companies have designed robotic hands and arms that gently grab different products and place them into the appropriate package. These systems are currently being employed in produce operations, snack foods, bakery items and proteinaceous products, such as fish and meats. The robotic systems are faster than humans, and there are no concerns about repetitive motion injuries. One of the manufacturers of this technology is a company called Soft Robotics Inc. (www.softroboticsinc.com ). These systems can even be adapted to handle leafy greens, such as romaine lettuce, which was implicated in several foodborne outbreaks. Eliminating the human element could help minimize the potential for cross-contamination.

One of the best applications for robotic systems is sorting for quality or other attributes. Sorting technology has made incredible strides in recent years. Sorters utilize lasers and various kinds of optics to detect defects. Optical sorters can do things like count the slices of pepperoni on a pizza, be programmed to remove materials that are different colors, or utilize different wavelengths of light to eliminate specific defects. Multispectral analysis has been utilized to detect grains, seeds and nuts that have been contaminated with mycotoxins. As an example, aflatoxins will fluoresce under ultraviolet light, allowing contaminated nuts, such as almonds or peanuts, to be removed from the process flow. The European equipment manufacturer, Bühler, has developed a system called the LumoVision that utilizes this technology (https://digital.buhlergroup.com/lumovision).

Mycotoxins, such as aflatoxin and fumonisin, are products of fungi metabolism and have been associated with the development of cancers in persons exposed to these metabolites over time. Being able to remove contaminated seeds, grains or nuts will enhance human health globally.

Perhaps the most common and most effective use of robotics in the food industry is in packaging, casing and palletizing. These actions of repetitive, and hence, very applicable to being automated. An automated or robotic packaging system can form the packing case, fill it with the item being cased, seal and code the case, and then lift it to the awaiting pallet. Depending upon the product being produced and the size of the case, the system will be programmed to build the pallet utilizing a designated pallet pattern. If one is packaging a frozen product, such a pallet might be designed with windows to allow better movement of cold air. Canned foods or snacks might go into a square or rectangular pallet pattern. This kind of repetitive motion that a robot does so effortlessly is the type of activity that often results in repetitive motion injuries for the crew working at casing and palletizing. These systems can also be designed to automatically feed pallets to the palletizer. Human intervention is often limited to getting the stretch wrap machine started by inserting the wrap between two rows of cases. Some companies such as Frito-Lay have robotic systems for transporting and storing pallets in the warehouse. The transporters are slow-moving crawlers that follow preprogramed paths and are also programed to stop if they sense someone or something in their way.

Statistics show that the use of robotics in food processing is increasing at a rate of approximately 17% a year. The best potential applications for robotics are those that involve repetitive motions or actions and deal with products that are somewhat uniform. With increasing computer power and the expansion of artificial intelligence (AI), the application of robotics in the food industry will continue to expand.

Will we ever get to the point that robotics will completely replace human beings in food processing? There are some operations that have evolved to the point where there are only a few persons needed to run the facility. An example might be the bakeries making buns for McDonald’s. But there are no fully automated food processing plants, and it will probably not become a reality for at least another generation. Asimov’s world of robots is still far in the future.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?t=1721343192)