Case study: C&M Seeds' expansion boosted by self-cleaning tubular chain conveyor from Luxme

In the last 18 months, Luxme International has installed a Tubular Chain Conveyor with automatic Stay Clean technology to meet the expansion of C&M Seeds’ primary processing and storage facility in Palmerston, Ontario.

In the last 18 months, Luxme International has installed a Tubular Chain Conveyor with automatic Stay Clean technology to meet the expansion of C&M Seeds’ primary processing and storage facility in Palmerston, Ontario.

The North American seeds market is expected to grow annually at a CAGR of 6.9 percent between 2020-2025,[1] with Canada contributing significantly to the continent’s 35% of the global market share. Sitting firmly at the center of the nation’s first link in the agri-food chain is C&M Seeds, a small but significant supplier of red wheat genetics and marketer of soybeans, barley, oats, and mixed grains.

When the company undertook a 30 percent storage capacity expansion project to its primary facility, a sealed, top-of-silo handling conveyor was required to meet growing business demand. C&M Seeds outlined dust control, durability, and easy maintenance as key criteria for the transportation system at its Ontario seed processing facility. The capability to withstand harsh environments and eliminate the risk of cross-contamination between seed batches were most important.

After receiving proposals from a number of machinery developers, the company was won over by the performance, reliability, and design benefits of Luxme’s automated Tubular Chain Conveyor with Stay Clean technology. “Our project team, operators, and management felt this was the best option to achieve our need for very high-quality operations,” said Rob McLaughlin, sales & marketing manager, C&M Seeds.

Removing the risk of cross-contamination

As a supplier to over 200 seed retailers and countless farmers across eastern Canada and beyond, C&M Seeds needed to improve the process of transferring finished batches to one of eight silos while maintaining the highest standards of quality. As a Certified Seed producer, the firm has earned its respected reputation and accreditation by following a rigid set of quality control standards set out by Canada’s Plant Breeders’ Rights (PBR) Act. In order to eliminate the risk of cross-contamination, these standards have to be maintained when transporting the company’s seed species—including winter wheat, spring wheat, and soybean—to the silo for storage. The challenge was achieving this with one machine.

Explaining the issue, Rob says: “Our business depends on supplying 100% pure seed stock; just one kernel can contaminate a batch, which we work very hard to avoid. Any contaminating variety of seed will create serious complaints and lead to significant losses for the retailer.”

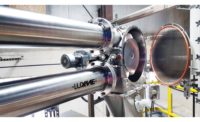

Luxme presented C&M Seeds with a solution: the food-grade Tubular Chain Conveyor with automatic Stay Clean technology. The system ensures a clean operation without cross-contamination between seed batches thanks to its self-cleaning technology. A chain disc tipper, disc cleaning brush station, and wiper discs clean out and purge the machine of any product, before operators inspect the interior for any visible residue after each batch.

Elaborating on the benefits of the Stay Clean technology, which includes gentle product handling to convey seed stock without breakage or product degradation, Rob states: “As the machine runs, it cleans itself and purges any random seeds. These are cleaned off the equipment and delivered back to the designated silo they were initially intended for. Also, we have noticed that there is no additional damage to the seed after the cleaning process – a definite plus compared to other handling lines, such as augers and individual bin downspout systems.”

The self-cleaning technology has reduced maintenance costs and contributed to higher ROI. Since installation in June 2019, Rob reports the company has saved two hours of washdown labor time between each batch, adding: “We have had to service the system much less frequently than other equipment and technology we have used in the past.”

Built to last through rain or shine

In addition to eliminating the potential for cross-contamination, protecting the product from external influences was also crucial for C&M Seeds. Since the conveyor is required to operate over 78-ft high silos throughout the four Canadian seasons, consistent performance with minimal maintenance were important factors due to the associated cost and difficulty of servicing equipment at high elevation.

Discussing the project, Rick Leroux, vice president and general manager at Luxme, says: “Our conveyor needed to run clean without carry-over and operate reliably outdoors with minimal service. It had to be insensitive to weather conditions and deliver worry-free operation 12 months a year.”

Rather than commissioning an off-the-shelf unit, the Luxme team worked collaboratively with C&M Seeds to engineer a unique transportation solution. Designed for high reliability, the conveyor runs with minimal power consumption at 7.5 HP with full load start and stop capabilities. It operates quietly as it transfers product to any one of six electrically operated, high efficiency Luxme rotary valves, which direct segregated and cleaned seed batches to any of the eight new storage silos.

The Tubular Chain Conveyor now performs at capacity with a throughput of 21,000 bushels-per-hour, receiving material from a bucket elevator that transfers the seed vertically to the top of the silos. Using a VFD drive, operatives can increase or decrease speed as necessary, allowing the conveyor to match the speed of the cleaner at the final stage before storage.

A heavy-duty framework and durable components provide protection against the harsh, changeable environment of its location. These components include: a case-hardened chain; high efficiency, electrically operated rotary valves; continuous cleaning and purging of dust and moisture with a combination of wiper discs, disc tipper, and rotating brush assembly; and a continuous chain tensioning device. An enclosed design eliminates any dust generation and protects the seed from moisture, water, and outside contaminants while moving through the pipe.

Taking safety to new heights

Another advantage of Luxme’s Tubular Chain Conveyor is improved health and safety. Beyond low maintenance and a highly efficient and effective process flow, it was imperative for the wellbeing of C&M Seeds’ workforce to remove the need for regular high-risk, outdoor servicing. The automatic Stay Clean technology, robust design, and a fixed drive with self-regulating continuous chain tension assembly means a safer operation for staff members, reports Rob: “The conveying solution from Luxme has allowed us to significantly reduce our hazardous, elevated work practices; much to the benefit of our employees.”

Commenting on the installation, he concludes: “We have noticed the operation is worry free. All we have to do is set the speed at the start of the batch and just let it run. The C&M Seeds team is extremely satisfied with the innovation and support provided by Luxme for this important step in our expansion process; we will definitely look for other areas in our business where a Luxme unit will fit.”

[1] https://www.mordorintelligence.com/industry-reports/north-america-seeds-industry

About Luxme International:

Established in 1979, Luxme International Ltd has grown to become one of the leading providers of Tubular Chain Conveyors and other material handling technology worldwide. With over 40 years of experience and thousands of satisfied clients, Luxme International offers high-quality material handling products and superior customer service, with extensive experience in solids handling systems. The company operates primarily in the agricultural, energy, manufacturing, mineral, chemical, pharmaceutical, and food industries, engineering and manufacturing complete conveying systems to meet individual customer needs at very competitive prices. All potential clients are invited to visit Luxme’s test facilities and showroom, both located in Montreal, Canada, to see the tubular chain conveyors up close and operating.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.jpg?height=200&t=1647013201&width=200)