Food Safety: Of the Package, by the Package, and for the Package

Providing safe food requires both safe food packaging materials and risk prevention by that packaging. As an integral part of the food supply chain, packaging may pose biological, chemical, or physical hazards to the food supply. But as soon as packaged food leaves the managed confines of Good Manufacturing Practice (GMP) zones, its package mitigates the environmental hazards encountered between the packaging room and the point of consumption. The hazard analysis for a food processing facility typically begins at the receiving dock and ends at the shipping dock. A packaged product’s package goes with it long after it is shipped. While each element of the food supply chain, such as shipping, storage, and retail display, has defined food safety practices, the package is present literally as another layer of protection for the food until its consumption.

When you come right down to it, the package does more than providing package functionality by containing, protecting/preserving, transporting, and describing its product. The core mission of a package is to “to escort its product from producer to consumer.” The descriptive labeling on a retail package functions as a “silent salesman.” Similarly, its protective function serves as a “silent Preventive Controls-Qualified Individual.” The quality adage “Do it right the first time!” sums up the food safety importance of having the right product in the right package

Any Hazard Analysis and Critical Control Points (HACCP) plan that identifies a “kill step” as a CCP makes packaging’s hazard mitigation role obvious. Once the process kills contaminating biological hazards in a product, the product relies on the package’s integrity. Its package isolates the product from later contamination: Retorted food is not sterilized until in its hermetic package; aseptic food, once uncontaminated, does not leave its aseptic surroundings until it is packed in sterile packaging; hot fill foods provide thermal energy to kill any pathogens on the food contact surface of their packages.

Processes without a kill step assume that any infectious bioburden in or on packaging materials will be small or able to increase very little or not at all. Biological contamination by packaging is rare. Package material GMPs reduce or eliminate these biological hazards. Packaging materials represent a much lower risk of biological contamination because bacteria, viruses, and mold spores may survive on the surface of most packaging materials. Those that are present will not thrive and grow on packaging materials (with the possible exception of paper packaging). In the U.S., only food packaging materials for products subject to the Pasteurized Milk Ordinance require ongoing monitoring for hazardous bioburden surrogates.

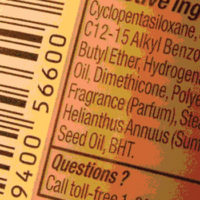

As a result, chemical and physical hazard mitigation becomes the critical hazard analysis focus for packaging material. Food safety efforts include a long history of concerns about the packaging chemical hazards. This includes migration of chemicals from package materials (e.g., lead solder once used for three-piece metal cans). And physical hazards also from brittle contamination from container material (e.g., glass shards broken from a bottle neck’s threaded finish from excessive force when applying its closure).

Packaging design and specification procedures provide the most reliable and efficient practices for preventing chemical and physical food hazards from packaging. Designers require information from food processors about the type of food and the use conditions, especially time and temperature, that food in its package will experience. Critical-use conditions include how consumers will use the packaging (e.g., using a microwave to reheat food in its package). Successful food safety management systems assure that these design considerations are implemented throughout the entire packaging manufacturing process. Procurement, receiving, storage, labeling, material allocations, and process control procedures must verify that manufactured package includes the preventive controls designed into a package.

The right package combined with effective processing using GMPs can minimize or eliminate the need for chemical preservatives. In spite of this, once that package is opened in households or institutions, new exposure to biological hazards must be confronted. Label cautions to “refrigerate after opening” provide users with an onboard lesson in “Good Consumer Practices.”

The essential safety of the packaging materials themselves is regulated in developed economies by science-based risk analyses performed by regulators to clear and list specific materials for food packaging use. Knowledgeable packaging design, procurement, and qualification of those materials effectively applies the expert risk analysis to the mitigation of chemical risk in subsequent good manufacturing, transporting , warehousing, and retailing practices. In turn, these good practices eliminate or minimize biological and physical hazards that packaging materials might represent.

The right package combined with effective processing using GMPs mitigates the risks of allergen hazards found in some foods. Figure 1, from the U.S. Food and Drug Administration (FDA)’s Reportable Food Registry shows for the 12 months from September 2009 to September 2010, products with labels failing to declare allergens resulted in about one-third of national recalls. Only Salmonella contamination caused more recalls in that period. Unfortunately, FDA experience since then reports undeclared allergen-related reportable food reports have steadily increased. The category rose to 47 percent of incidents in the year ending with summer 2014.

| Figure 1. Reportable Food Registry Recalls by Food Safety Hazard (9/2009–9/2010) |

Since its proposal in 2011, the initial documentation of prerequisite programs (PRPs) for food packaging material safety, Publicly Available Specification (PAS) 223, specifically addressed PRPs for food safety that apply to food and drink packaging design and manufacture. Its Chapter 17 requires, “Where packaging is printed with food safety information, measures shall be in place to verify that the information is compliant with customer requirements. (Note: Food safety information includes (but is not limited to) ingredient lists, allergen statements and instructions for use.)”

Unfortunately, the majority of recall incidents for undeclared allergens represent products that unintentionally contain allergens that were not identified or planned by the processor at the time the packaging or label information was printed. A processor who manufactures products, some containing allergens and some not, must develop, train, implement, and document procedures to put each product in its intended pre-printed packaging, A warning letter from FDA to a food processor demonstrates the complexity of such procedures to correctly match pre-printed packaging to each specific product. The FDA inspection reveals the critical role of record keeping in verifying that the procedures are followed and demonstrates that the wrong product in the right package represents a food safety hazard. Food processors must develop and implement preventive controls to assure each product is in its right package—the one designed and manufactured with its safety in mind!

Thomas Dunn is an independent consultant with EAS Consulting Group. He has designed and developed food packaging materials for 40 years.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!