Extending food and beverage shelf life through packaging technology

The correct packaging can make a big difference in food and beverage shelf life, and there are different techniques to prevent leakage and spoilage, as well.

Viking Masek (Oostburg, WI) has been participating in the development of the new STANDCAP packaging technology and has designed a machine to fill and seal STANDCAPs, says Scott Miller, vice president of product and technology.

"Through the ongoing process of qualifying potential candidates for this technology we have learned that with market testing and shelf life analysis the results customers are seeing is substantial. Recently one of our customers shared with us that the shelf life for their guacamole product went from just a few days to six weeks and potentially beyond," he comments.

The STANDCAP originally designed and patented by Daisy has seen great long term improvements for usability as well as well as extended shelf life, he says.

"The opportunity for this style of packaging is endless when considering the possibilities of liquid packaging and how many different products are currently packaged in rigid containers," says Miller.

Holly Dunnill, North America food & specialty packaging marketing director, Dow Chemical, Houston, says that Dow provides the broadest portfolio of applications to address growing demand for packaging solutions that improve product shelf life and reduce food waste.

"Resins like Surlyn, AFFINITY and Elite AT present seal integrity and puncture resistance, ultimately meeting consumer demand for stronger, safer packaging in the food industry," she remarks.

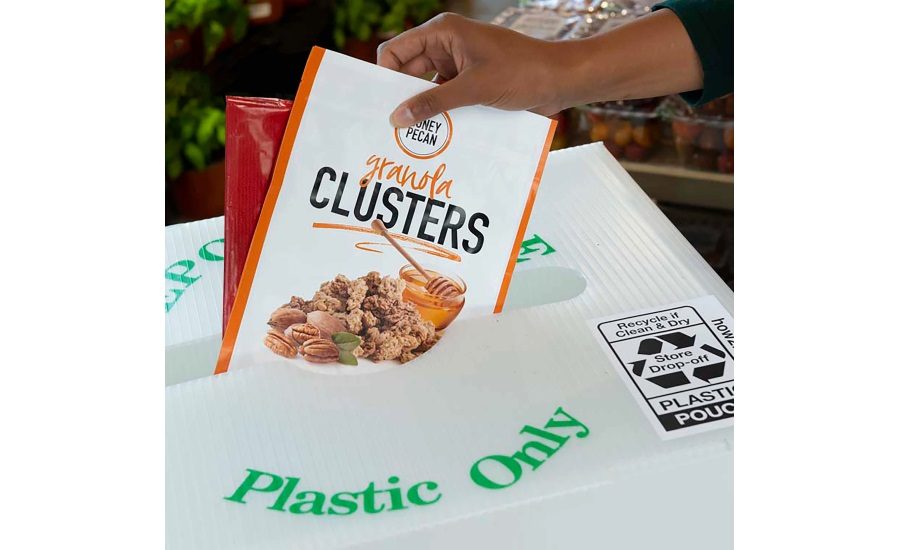

Designing for recyclability, a major trend, has been the focus for years at Dow, and as technologies evolve, they have responded with new consumer-driven products, such as their RecycleReady pouch.

"The stand-up pouch made with RETAIN polymer modifiers is the first package of its kind with barrier film that can be recycled in a polyethylene recycling stream. When combined with other polyethylene resins, the RETAIN compatibilizer offers a recyclable solution with complete hermetic seals to avoid leaks," says Dunnill.

"Another trend we’re seeing is the increased need for toughness in packaging, especially with the rise in e-commerce. Our INNATE Precision Packaging Resins are a new family of resins that address some of today’s more challenging packaging performance gaps with stiffness in combination with excellent tear and puncture resistance."

For the dairy, beverage and snack food industries, Dow’s APPEEL product provides an easy and effective way to not only improve the convenience of peelable lids for retortable polypropylene (PP) packages, but to protect the contents by ensuring sealing integrity, adds Dunnill.

"Dow’s AFFINITY polyolefin plastomers (POPs) are designed for enhanced caulkability and hot tack strength. These properties enable hermetic sealing at higher speed, weight or stress resistance in the seal areas, and can seal well through layer transitions, gussets, voids, wrinkles or contamination," she comments.

"Dow is also focused on advancing barrier technology that can lead to an extended shelf life for frozen and snack food products. Dow has the broadest portfolio of applications to address growing demand for packaging solutions that improve product shelf life and reduce food waste. Resins like Surlyn, AFFINITY and Elite AT present seal integrity and puncture resistance, ultimately meeting consumer demand for stronger, safer packaging in the food industry," Dunnill notes.

According to Dunnill, Surlyn presents a down-gauging opportunity for the packaging industry while meeting higher expectations and reducing total costs. The resin comes in a range of grades that provide outstanding combination of attributes, including:

- Stiffness

- Formability

- Puncture and abrasion resistance

- Excellent sealing

- High clarity

- Finally, when it comes to extending shelf life through moisture barrier, Dow Chemical's ELITE AT Advanced Technology Resins builds on the reliability and uniqueness of INSITE Technology and gives much greater flexibility to tailor the molecular weight distribution, short-chain branching distribution, and long chain branching specific to an application's end-use requirements.

Jorge Izquierdo, vice president of market development, PMMI, The Association for Packaging and Processing, Reston, VA, says that he continues to see the emergence of packaging technologies that prolong the freshness of food and beverage products.

"In the manufacturing facility, high pressure processing (HPP) is gaining tremendous popularity for its ability to use methods that do not rely on additives or conservatives such as cold water and extreme pressure to minimize foodborne pathogens and organisms that contribute to spoilage. In the retail setting, modified atmospheric packaging (MAP) and oxygen-absorbing films can prevent oxidation in flexible and tray formats to combat premature expiration of fresh meats, fish and produce."

Once in the hands of the consumer, resealable packaging closures including adhesive strips, zippers and hook-and-loop fasteners mitigate degradation from oxygen to extend repeat product use, he adds.

"With the packaging landscape ever evolving, manufacturers can utilize resources such as the Cold Pressure Council (CPC) to discover more about HPP and its applications. PMMI also provides a number of business intelligence reports exploring advancements in packaging to prolong freshness—most of which can be seen in action at shows like PACK EXPO Las Vegas."

Bill Burnard, business development manager, package integrity group, INFICON, Cologne, Germany, says that when you consider what's possible in a laboratory, versus what's practical in a production environment, things can be really different.

"When a product is being produced literally hundreds per minute, things have to really be very precise and repeatable, to get the kind of outcomes that a manufacturer needs. This is really the point of every piece of packaging equipment companies make and purchase," he says.

Sealing a package, especially in flexible packaging, is really a complicated process, and there's a ton of variables to consider, Burnard adds.

"Things like film thickness, sealing variables, like temperature, build upon the sealing bar, or the surface of the material, roll to roll film variables, speed of the feet of the films. You throw in on top of that operator variables and even shift to shift variables. So how it impacts the food spoilage and shelf life, it's almost innumerable, but it almost always leads back to leakage of some sort or another."

He says that typically, original equipment companies take a lot of energy to ensure the control of the important variables. However, if a market in the products change, there are things that add complications, or as yet to be determined variables that haven't been engineered out.

"One simple example of this trend could be the emergence of biodegradable packaging, as well as a lot of companies following a simultaneous trend towards more natural products at fewer preservatives. These two topics are essentially diametrically opposed when you consider food safety and shelf life," comments Burnard.

The removal of preservatives is simultaneously making packaging more biodegradable, he notes.

"Thus, sometimes when a company is trying to extend their machinery useful life, concessions need to be made and this is just one example of where leak testing can become a critical in an operation's productivity and cost."

Burnard explains that leakage is a safety issue, especially in products like bacon, because of the contamination.

"When you look at it, in terms of safety and in terms of cost, there's some hidden unintended circumstances that you might not find there. For example: one of a bacon company's main concerns was the costs and the contamination associated with leakage of the fluid out of the bacon after it [been received at] the grocer. Because what happens there is that you have a leak in your product, and it spills out onto the other product and into the display, and the whole display has to be cleaned and sanitized. This promotes a really significant and negative experience for the consumer, touching product that's leaking and having to constantly wipe their hands. It creates a cost associated for the grocer and it creates a cost for the manufacturers."

INFICON's Contura technology can be used for machine optimization, says Burnard, and has an accurate leak rate.

"One of the interesting observations that we've had with regards to the Contura is that it can also be used for machine optimization. The Contura is can be used for production machine optimization in our experience because it's leak rates are so much more accurate and sensitive, as well as it's faster, in terms of its leak testing cycle," states Burnard.

"There's a natural tension in between quality and in production, right? Quality is always like, 'Well, we want to make sure that everything going out the door is perfect,' and production is, 'I'm getting paid by the piece.' But because the leak detector can detect smaller leaks and do it faster, it reduces a natural tension within the plant. We've seen actually some really interesting dynamic changes within operations that they are more if you will, more appreciative of the quality assurance measures that can be taken. The Contura, because of its technique and its speed, can really enhance the collaborative efforts there within facilities."

The Contura works by creating a vacuum pressure that's essentially 10 times higher vacuum, or 10 times deeper vacuum, than any other testing techniques, explains Burnard.

"What that larger pressure differential does is that it allows us to detect even micro leaks. So you close the lid, it creates a vacuum around your bag of chips, the walls of our vacuum chamber they collapse around your bag of chips to reduce the volume and cradle very safely your packaging. Then any gas that leaks out is then very easy to detect because we have a very, very deep vacuum and very precise vacuum measurement instruments built into our leak detector," he says.

Burnard says that one of the things that Contura does nicely, that's almost impossible to do otherwise, is that it leak checks the entirety of the package.

"If you're doing bubble testing, essentially, you're doing a visual check for a bubble forming. There could be four or five different locations where very small leakage is occurring and bubbles are forming, but there between the four or five, they might add up together to make a leak rate that might form a bubble that you would notice. But independently, they're not leaking at a rate that creates the type of leakage that would be noticed with a bubble testings. With the Contura it does an aggregate exact leak rate," he comments.

"Even if each one of those didn't leak to a leak rate that would generate a bubble, let's say that would be visually caught, it will capture that information. It captures the total gas exchange and not just a gas exchange from the largest visible one. Safety-wise, this is really a big step forward for companies."

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!