Sanitation

BIZTRACKS

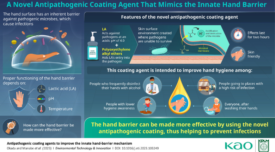

Scientists Develop Formulation That Boosts Antimicrobial Properties of Natural Hand Barrier

September 8, 2023

Never miss the latest news and trends driving the food safety industry

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing