Wayne Labs

Wayne Labs has more than 20 years of editorial experience in industrial automation. He served as senior technical editor for I&CS/Control Solutions magazine for 18 years where he covered software, control system hardware and sensors/transmitters. Labs ran his own consulting business and contributed feature articles to Electronic Design, Control, Control Design, Industrial Networking and Food Engineering magazines. Before joining Food Engineering, he served as a senior technical editor for Omega Engineering Inc. Labs also worked in wireless systems and served as a field engineer for GE’s Mobile Communications Division and as a systems engineer for Bucks County Emergency Services. In addition to writing technical feature articles, Wayne covers FE’s Engineering R&D section.

ARTICLES

Food Safety

With FSMA a done deal for food & beverage processors, compliance is more important than ever

Read More

Supply Chain

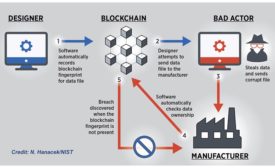

Fighting food fraud with the right tools

Analytical and software tools make it easier to manage suppliers and weed out fraudulent ones

October 5, 2018

Automation Series

The challenges of upgrading legacy control systems

A legacy control system may be running just fine, but processors need to be prepared to replace it

October 5, 2018

Manufacturing News

Local food still raises safety concerns

Auburn University project aims to improve food safety in local products

September 17, 2018

Food Safety

ANSI certifies Perry Johnson Registrars Food Safety Inc. under new FDA program

FDA’s Accredited Third-Party Certification Program covers four main categories in food safety including preventive controls and HACCP

September 5, 2018

Manufacturing News

New bioengineering labels are on the way

Labels will show foods are compliant with disclosure standards

August 8, 2018

Never miss the latest news and trends driving the food safety industry

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing