Articles by Neal Lorenzi

Research and product development are moving at a rapid pace

Read More

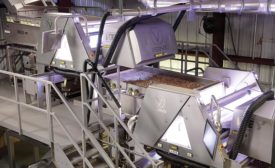

Inspection and detection equipment reach new levels of flexibility for peak food safety

X-ray, metal detection, checkweighing and vision systems help processors ensure food safety

January 22, 2019

Third-party logistics providers integrate warehousing and transportation

Snack producers and bakers can customize warehousing and transportation services to meet individual needs.

June 8, 2018

Packaging trends keep snacks and baked goods fresh and safe through shelf life

Modified-atmosphere solutions and active packaging technologies lead developments in packaging safety

May 2, 2018

BISSC standards help snack and bakery equipment manufacturers ensure peak food safety through sanitary design

The latest snack and bakery equipment follows BISSC standards to minimize the possibility of food contamination.

March 21, 2018

Selecting the right inspection and detection equipment for snack and bakery operations

Refinements to inspection and detection equipment boost production safety and quality.

January 15, 2018

Improving the food industry cold chain with interconnectivity

Food temperature monitoring and tracking technology reaches a new level.

May 18, 2017

Never miss the latest news and trends driving the food safety industry

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing