Preventing pests in food handling, packing, processing and storage facilities

Pest prevention is an important part of food safety. If you have pests that get into your product, the product is obviously then unusable, and the recall alone can leave your business with a bad reputation.

Best practices

“Good pest prevention starts with awareness,” says Jeff Waggoner, vice president/general manager, Fumigation Service & Supply, Westfield, IN. "I understand there are many items to look at and a lot of boxes to check but, like people, facilities are very dynamic. The basics remain the same but you have to assess and build awareness.”

“You become aware of your risk level by knowing several things. Your facility, your systems, your resident and inbound pressures, your pests themselves and your partners in prevention. Your risk is all relative to these factors. You come to know each of these factors intimately and you will not have a problem with prevention because your support system is strong,” he says.

“Don’t know what the target pest is and you may be treating the wrong location with the wrong approach or chemical. Don’t know your partners’ capabilities, limitations or not communicating properly and bottle necks occur and things don’t get done, cleaned, reported, etc. I.e.: is this an internal problem with my facility or is this an inbound problem?”

Building a successful preventative program takes some time and coordination that not many can accomplish, notes Waggoner.

“Like a coach, if you don’t win you get replaced. If you win, you move on to the next level so the revolving door affect is also why the system is so important. A good system may sustain in the absence of a single point person but can equally collapse if that person carried a disproportionate amount of the burden,” he says.

“We profess to be the best at understanding the fundamental process in building a DynamicIPM program that works for each individual location. Analog or traditional cookie cutter programs that so often are the result of a corporate procurement process are absolutely counterproductive to our methodology of good pest prevention and a successful program. Despite the initial cost savings, these programs put the entire system and ultimately the public at risk.”

Dan Collins, regional technical director, McCloud Services, South Elgin, IL, says that every pest requires food, water and shelter in order to survive and subsequently infect structures.

“Insects also need sustained warm temperatures for survival (e.g., freezer storage is not always susceptible). However, preventing pests from gaining access and establishing within our buildings is fundamentally the same. Personnel at each facility type must be cognizant of the pest types that could severely impact their operations,” he says.

For example, food grade corrugate packaging facility personnel should be trained on how to identify psocids, minute brown scavenger beetles and other fungus dependent species that can survive and thrive on "non-food" materials such as moldy pallets and corrugate, Collins notes.

“Likewise, grain-based food manufacturing facility personnel responsible for inspecting inbound materials should have a good understanding of stored product insects, rodents and other potential hitchhikers on or within food ingredients and its associated packaging.”

Almost everyone in the food industry knows pest prevention starts on the exterior, Collins remarks.

“Flowering and fruiting plants should be avoided as should creeping plants such as arborvitae. If plants are used in landscaping, they should be vase-shaped and provide easy access beneath them for cleaning, maintenance and pest inspection. Mulch beds should be avoided at all costs at any facility type as they are highly conducive to pest threats such as rodents, termites and ants. Gravel or concrete is the best perimeter type for most food grade facilities. Gravel perimeters should be 36 inches wide with quarter inch gravel that can be compacted. This deters rodents and other burrowing pests from establishing next to exterior walls.”

Selecting exterior lighting that isn't attractive to insects should also be a top priority for food grade facilities, Collins notes.

“LED and high-pressure sodium vapor lighting is less attractive to insects and are the best lights to deter light-attracted pests like ground beetles and moths. LED lighting is oftentimes manufactured with "ultraviolet" lighting within the LED bulb so food plant and food-grade distribution centers should consult with lighting experts prior to installing LED lighting.”

If possible, lighting should not be installed by highly-used entry doors such as employee entrances, recommends Collins.

“Oftentimes, lighting near employee entrances is on motion detectors or timers to reduce light emissions, and thus pests, near these highly used footpaths. Pests can also enter facilities through dock doors and personnel doors so they must be well-sealed and closed when not in use. A quarterly preventive maintenance schedule focused on pest prevention can help reduce pest entry through these susceptible entryways.”

In addition, building materials are important to consider when constructing food-grade facilities, he adds.

“Corrugate metal and hollow block concrete walls, although cheaper than solid pour concrete walls, are much more susceptible to pest entry, harborage and infestation. Solid pour concrete is highly preferred over other construction materials for food plants. The same can be said for flooring, etc. Solid pour concrete floors with epoxy or other seamless, cleanable surfaces provide easier to clean substrates that are much less prone to pest and microorganism development.”

In order to stay pest-free, monthly self-inspections focused on sanitation, personnel practices, structural integrity, equipment design and so on can proactively identify and eliminate conditions conducive to pest activity, he says.

“Self-inspection teams should be cross functional with sanitation, maintenance, QA and plant management involvement. Pest management contractors should also have "built-in" inspection time during routine services to find and prevent pests before they establish and infest facilities. When pests are found or are captured in monitoring devices such as interior rodent traps, an action plan should be established to ensure no additional activity exists. If more activity is found, a more detailed corrective action plan with follow ups should be established until pest activity is eliminated. No matter what type of food facility you have, everyone at the facility must be engaged in the pest management program to proactively manage, prevent and minimize pests.”

One key best practice is to consider factors that may draw pests to facilities and any conditions that could allow pests entry into the buildings. The higher the attracting power, the higher the risk of the facility being penetrated by the pest, says Dominique Sauvage, senior director of field operations, training & quality, Copesan, Menomonee Falls, WI.

“The most effective way to prevent pests in food-related facilities is by making efforts to keep them from entering the buildings initially. Doors and windows should be kept closed whenever possible. Additional points of entry (cracks, gaps, tears in screens, broken vents, etc.) should be fixed or sealed,” he recommends.

A thorough inspection of the exterior of the building should also be conducted, focusing on any conditions that may attract pests to the building, Sauvage says.

“These conditions can include (but are not limited to) standing water, outside lighting, overgrown landscaping and dumpsters or garbage stored close to the building and exterior doors.”

The inspection of incoming goods is also an essential part of the overall program, as pests can be transported into a facility through an outside supplier, notes Sauvage.

“It is important to know who may be supplying you with pests in pallets and boxes. Teams should have a protocol in place for inspecting incoming trucks/shipments and an action plan to follow if pest evidence is found. Food production facilities may have a higher risk of attracting pests due to increased odors from production and waste.”

Michael Thome, technical services manager, Rentokil Steritech, Reading, PA, says that best practices for preventing pests in any commercial facility center on having an effective integrated pest management (IPM) program in place.

“IPM is a multi-pronged concept that involves using multiple strategies to keep pests from impacting structures and people through habitat modification, biological controls, improved sanitation, and education to change behaviors that may contribute to pest activity,” he comments.

There is no cookie-cutter IPM program that will work for every operation, Thome notes.

“Any number of circumstances can influence pest activity at a location: for example, geography; seasonality; the age and condition of a structure; neighboring properties; and most importantly, the products being produced, packaged, or stored and the processes involved in producing, packaging, or storing them.”

To determine the best practices and shape an IPM program for your operation, you should work with a qualified pest management provider that has demonstrated experience with successful programs for your type of facility, he recommends.

“If you have multiple locations, look for a regional or national provider who can help ensure consistent standards and protocols are utilized in all locations. Facilities assessing their pest management efforts can begin by looking at two specific areas that can greatly impact pest activity.”

The best way to keep pests out of an operation is to stop them from ever getting inside, says Thome.

“Even in the newest buildings, there may be structural issues that exist. Begin with an exterior inspection. If possible, this should be done monthly, but at a minimum, quarterly. Look both high and low to identify potential areas where pests may be able to gain access.”

He recommends looking at these areas during inspection time:

Ground level

- Are there gaps underneath any doors?

- Are doors propped or left open for ventilation?

- Are there any gaps around piping, cabling, or other penetrations into the structure?

- Are there any structural cracks or holes larger than ¼-inch?

- Is there any vegetation within 18 inches of the structure or touching/against the structure?

- Is there standing water anywhere around the facility?

- Are screens covering any ventilation or exhaust fans missing or damaged?

- Are gutter downspouts damaged or blocked?

Roof level

- Do any trees overhang or touch the roof?

- Is there any pooling water?

- Is there leaf debris or other obstructions that prevents gutters from flowing freely?

- Are screens around HVAC units or covering other ventilation missing or damaged?

“If you answer yes to any of these questions, there could be an opportunity for pests to access your structure,” says Thome.

Inspections

Rosy Brown, CEO, Rasco Industries, Inc., Mound, MN, says that loading dock doors must be down and locked for food defense and to prevent pests from entering the facility.

“Ventilation is required in some instances but that may allow pests in; screen doors may be the solution. An overhead screen door that works in conjunction with your loading dock may help. You’ve made a thorough analysis of your food processes, sanitation, and you’ve implemented and documented a pest control plan for your plant. What happens if a worker has left the loading dock door open and you get a surprise inspection?” she comments.

“It's not good, and here’s why: the loading dock area especially if you have garbage outside the dock area is a main point of insect and rodent entrance not to mention the threat of human intruders. Leaving a loading dock door open to every fly, rat and other vermin is not the way to get a good inspection report. One way to get an automatic assessment of unsatisfactory by AIB is your dock door not pest-proofed and rodent evidence noted in the facility.”

The reality of hot temperatures in the factory makes it hard to comply with keeping the doors always closed, she says, and a stainless steel screen door used as a barrier to pests and intruders might be the solution—happy workers, happy inspectors and peace of mind.

According to Rasco, the AIB standards for inspection include:

- Windows and doors that must be kept open for ventilation are screened to prevent pest entry.

- Ventilation is provided in product storage and processing areas to minimize odors, fumes and vapors.

- The building has barriers in place to protect against birds, rodents, insects and other pests.

- External doors, windows or other openings are close fitting or otherwise pest-proofed to less than 1/4 in. or 6mm.

- If practical or possible, physical security measures that can include: Locked doors and controlled access.

- Wildlife control measures are considered, where appropriate. Devices include: Wire, materials that prevent entry.

- AIB Integrated Pest Management states: "While it is important to remove pests from a facility, it is more important to prevent pests from ever having the opportunity to thrive in a packaging environment."

Thomas Nelson, senior staff scientist, Ecolab, St. Paul, MN, recommends the following for best practices in preventing pests in facilities:

-

Think outside-in: Make the outside environment around the facility unattractive to pests.

By removing sources of water, food, shelter and structure access, pests will find more attractive places to live – away from your facility. Deny pests water by eliminating puddles and other unnecessary water sources. Prune and maintain trees and shrubs to remove food (such as berries and leaves) and roosting sites. Keep trees and shrubs away from buildings to eliminate easy access to structures. Also, make sure trash receptacles are kept closed and clean up spilled ingredients to deny pests food. To further eliminate food sources as well as hiding places, keep grass cut and maintain weeds—a barrier of gravel, or other hard surface, next to the structures outside walls prevents grass or weeds from growing at that critical boundary. Note that many of these attractive conditions can occur on the roof tops of structures as well.

-

Keep pest prevention top-of-mind during construction and landscaping projects.

Pest prevention is often overlooked during landscaping projects and when conducting structural additions and repairs. Make time to consult a pest prevention professional to identify any potential pest-related risks that can be addressed in these designs before they are implemented.

-

Keep pests out of structures through good exclusion practices.

Keep doors closed and add automatic closures where practical. If entryways or windows need to be open, screens (minimum of 18 mesh, 30 mesh preferred) can be used to keep pests out. Tightly seal gaps under and around doors and utility access points, as well as cracks in a structure—a standard rule of thumb is to look for any visible light through an opening (just a ¼-inch gap is large enough for a mouse to pass through.) On roof tops seal gaps and cracks around hatches and building equipment. Knowing that birds will roost on rooftops, identify critical areas that birds need to be kept away from (doors, dock doors, critical equipment). There are a variety of bird exclusion devices that can be installed to keep birds away from these critical areas. In addition, a pest professional can offer proactive solutions such as identification of potential pest entry risks, exclusion services to prevent pests from getting in and proactive applications of products to areas of higher risk and prior to times when pest activity on the exterior increases.

-

Inspect incoming materials.

Incoming materials can also be a route that introduces pests into a facility. Best practices include keeping pests out by establishing material inspection protocols with sample sizes and inspection frequencies based on history and potential risks. Know what your high-risk materials are and if there is a history of contaminated materials from specific suppliers. Inspect pallets and bulk containers. Look for actual pests and signs of pests such as container or product damage and rodent or bird droppings. Visually inspect packaged materials and samples of bulk materials with the aid of a sieve. Prevent introduction of pests further into the facility by isolating contaminated materials in a designated “quarantine” area at the incoming delivery site.

-

Train staff and follow GMPs.

Doing everything that can be done to keep pests away from and coming into the facility reduces the number of pests that do get in. Use your GMP’s to help prevent pest activity. Employee training is critical and can help them understand and identify pest activity or the potential risks for pest activity. It can help them understand how their actions can introduce risks such as leaving doors open, bringing pests from other locations, not following protocols or SOP’s. Management of inventory is also important in preventing pest activity. Using first-in-first-out inventory practices, as well as identification and inspection of materials less frequently used, reduces risk that pests will develop and infest inventory.

-

Conduct regular inspections.

You and your pest provider must continuously inspect and monitor the interior areas of a facility to prevent pest issues. Conduct regular, thorough visual inspections looking for sanitation and structural issues that may become conducive to supporting pest activity. Place monitoring and trapping equipment in the facility based on risk. Data from monitors and traps aid the inspection. For instance, a rodent caught in a trap, excessive numbers of flying insects in a light traps, or stored product pests in pheromone monitors should raise questions and trigger a thorough inspection in that location. Data from traps and monitors can be used to assess trends and establish thresholds.

-

Eliminate conditions that can contribute to pest activity on the interior of the facility.

Know the specific best practices for your industry to keep a clean facility. Develop a Master Sanitation Schedule (MSS), adhere to it and assign an associate to be accountable for it. Monitor and document cleaning as a component of the MSS. Your pest provider may find pest conducive conditions during their inspection. Develop and act on corrective actions for sanitation or structural findings.

The prevention measures described above are universal and apply to all producers of food. Each facility is unique and how pests are prevented can depend on variables such as the type of food produced, the process used to produce and/or age of the production facility, pressure from the exterior environment among others, he says.

“Pests that pose the biggest risk can vary by industry—flies may be a major problem for a meat producer while stored product pests may be the primary issue for a pasta plant, but the approach described above will prevent these specific pests. Work with your pest provider to develop an effective pest prevention program that will keep pests away from and out of your facility and take care of the pests that do get in.”

Sanitation

Sanitation both on the interior and exterior of a facility can dramatically impact pest activity, says Thome.

“Food processing, packaging, and storage/warehousing businesses often face challenges due to the 24/7, round-the-clock operation of facilities; it can be difficult to find down-time to do the deep-cleaning needed in many areas. However, to prevent pest issues, it is necessary to find that time,” he recommends.

There are general principles that any facility can put into place, he says. Review your sanitation program and ask the following questions:

- Are any food spills cleaned up immediately and removed to trash areas?

- Is the facility's janitorial or cleaning team properly staffed for the size of the operation?

- Does the janitorial staff receive thorough training to know proper cleaning procedures and do they understand high-risk areas that need extra attention?

- Is there a quality assurance process in place for janitorial or cleaning staff to ensure that all necessary actions are completed after each shift or day?

- Is there a preventative maintenance plan in place for all drains in the facility?

- Are there daily, weekly, and monthly checklists for equipment maintenance and cleaning? Are those checklists followed and used on the prescribed basis?

- Is there a regular deep cleaning process in place for food storage racking areas?

- Are trash and waste areas well maintained, kept as neat as possible and cleaned on a regular basis?

- Is there an inspection process in place for incoming goods or supplies and is it thoroughly followed?

If you answered no to any of these questions, the sanitation practices in place may provide an opportunity for pests to invade, feed, or breed at your operation, says Thome

Once a pest management program is in place, it should not be a "set it and forget it mentality,” he notes.

“An operation's pest management program should evolve with the circumstances at your facility. Any change in pest activity levels, seasonality, extreme weather, new products and processes, new suppliers, construction and remodeling, and new neighboring properties are just a few of the conditions that should prompt an overview of your program and modifications to accommodate changing risk. “

Rentokil Steritech talks about pest management as a partnership with our customers, says Thome.

“It is important that every operation has a strong relationship with a pest management provider that knows its facilities. Allow your pest management provider to talk to staff within your operation and get to know people at different levels: from your cleaning crew to line workers to administrative and management staff. Employees at food processing, packaging, and storage/warehousing operations see things every day and may have information or insights that help your pest management provider zero in on problems or behaviors that could be contributing to or conducive to pest issues.”

It is also important to look at and act on the data you get from your pest management program, he recommends.

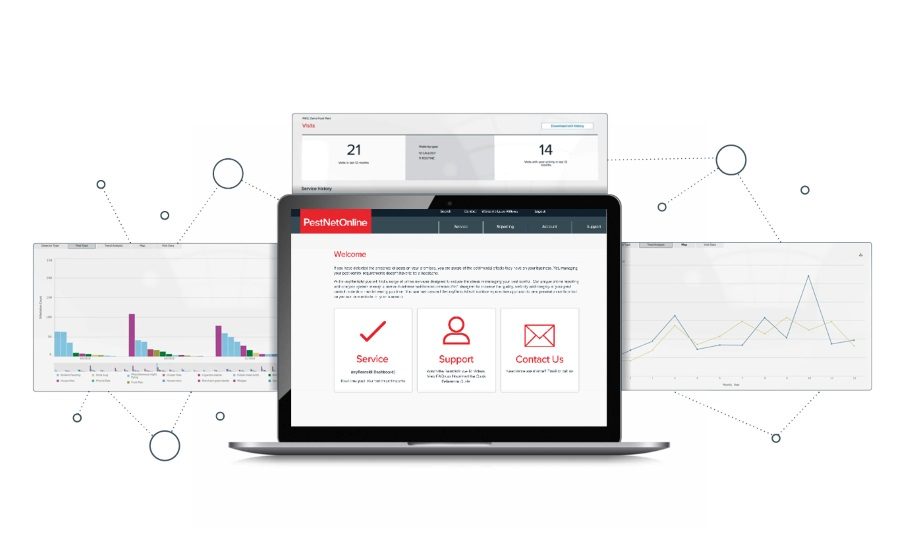

“Does your provider offer an online system that provides you with service data and recommendations? Can you trend your pest management data over multiple years or seasons to identify potential risks or needed actions? For example, Rentokil Steritech's PestNetOnline system allows you to view recommendations made at a facility and whether or not corrective actions have been taken on those recommendations. “

Particularly with sanitation and storage practices, the steps that need to be taken will vary widely based on what the facility does and the products it produces, packages, or stores, Thome says.

“In other words, your IPM program should be tailored to your facility and its unique needs. In fact, under the Food Safety Modernization Act and many third-party audit standards, pest management programs are required to be risk-based—meaning that the facility and its staff are responsible for ensuring that pest control efforts are in place to control specific risks to your product, facility, and operation.”

For example, a facility processing chicken may have an increased risk of flying insect activity because the product and its by-products are more attractive to flies, while a facility storing grains may not need as robust of a flying insect program, but may need to amplify its measures to prevent stored product pest activity, he notes.

Checking for pests

“’Prevention’ is a hallmark of recent Food Safety Modernization Act (FSMA) legislation and regulations,” says Jerry Heath, product manager and staff entomologist, The Industrial Fumigant Company, Lenexa, KS.

There has been a shift of emphasis from monitoring processes and reacting, to assessing risks and finding preventive measures that can be put in place, he adds.

“Rules and regulations stemming from FSMA build upon the rules and regulations commonly known as ‘Good Manufacturing Practices’ (GMP’s) which guided the industry for years on how to avoid adulteration. Aside from regulatory requirements and enforcement the food industry is largely self-policing,” Heath notes.

Successful companies have rigorous sanitation and quality standards. And, at every level of the industry companies are sending out auditors (inspectors) to be sure their suppliers are maintaining high standards, he says.

“Some companies have ten or more different auditors checking their facility annually. Standards or specifications may be dictated by a company for their suppliers of all kinds of ingredients and supplies, or there may be widely applicable standards developed by third party organizations. This is the basic scheme behind the Global Food Safety Initiative and audit standards developed by organizations such as the British Retail Consortium (BRC), Quality Safe Food (QSF), American Institute of Baking (AIB), and others,” Heath explains.

These standards often encompass the main regulatory requirements as well, he says.

“It is remarkable to consider the reach throughout the entire food industry from standards dictated by one conglomerate of fast food restaurant brands, for example, on all the components that go into their menu items: meats, seafood, breading for fried foods, fresh and processed vegetables and condiments, dairy products, baked goods and so on.”

Prevention begins with doing the best possible job of pest exclusion, sanitation, harborage elimination, inspection to avoid importing pests and identifying conducive conditions to correct before something develops, and preventive treatments to keep certain perennial threats at the lowest possible population levels, Heath remarks.

“Audit standards go a long way in dictating integrated pest management practices as they require documentation of many sanitation, inspection, and monitoring tasks. Successful pest management requires excellent coordination and communication between many departments in a plant, and a high quality and professional pest management service provider. There are significant differences in the range and quality of pest management services being offered to the food processing industry. Cost of service is important, of course, but not so much as the risks associated with inadequate or sub-standard service.”

Challenges and solutions

The enactment of the Food Safety Management Act (FSMA) has presented challenges for all stakeholders (Pest Management Professional [PMP], Food Safety Manager [FSM], Auditor) involved in establishing and maintaining pest free-conditions, says Joe Barile, technical service lead, pest management and public health, Bayer CropScience, Cary, NC.

“Given that the Act now requires that action must be taken proactively before pest activity rather than reactively after pest activity has been discovered, requires a strong, open level of communication between stakeholders and the commitment to act when pest-conducive conditions are discovered and reported,” he says.

The foundation of providing an effective program is found in providing the first component in an Integrated Pest Management approach; a comprehensive, detailed inspection on every scheduled service, Barile recommends.

“Food manufacturing environments are complex and provide suitable resources for pests to gain entry, find shelter and reproduce. Historically, PMPs have fallen into the routine of checking and coding rodent traps that are placed at regular intervals throughout the facility. This practice is so time consuming that the PMP rarely has time to inspect, record and address other pest conducive conditions or activity that may exist.”

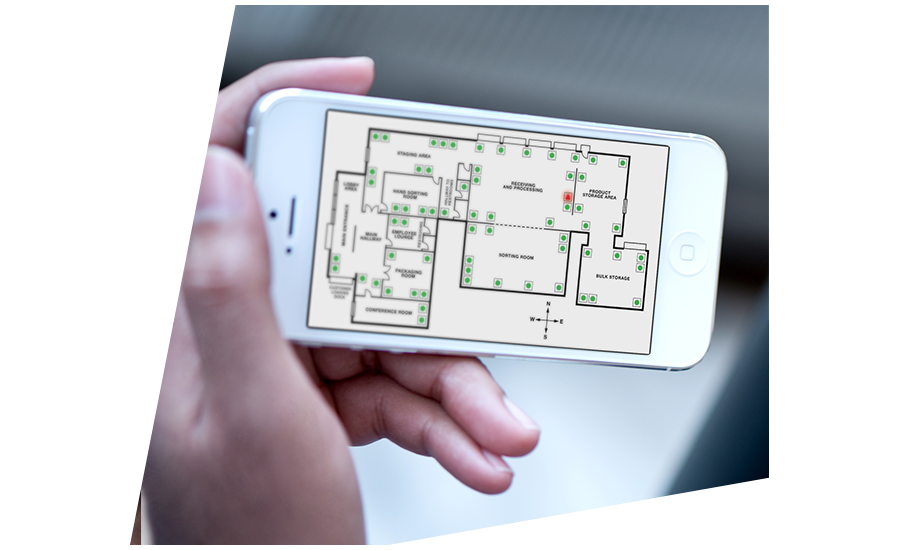

Fortunately, new technology developed to create remote rodent monitoring systems can support the detection and create a database where stakeholders can mediate risk before an infestation can grow unchecked, he notes.

“But even with new digital technology, the key to results and compliance with the Act is to create the effective partnership between stakeholders. FSMs should reach out and get to know all the key partners of their pest management service providers. Meet regularly—I suggest quarterly, if risk is low—with the PMP representative—not the technician—that is responsible to your facility. Including a representative from your auditor is strongly suggested. They can provide a valuable perspective on pest challenges. Commit to action when activity, observations and recommendations are provided and as a team, follow-up on action plans when produced,” comments Barile.

“In my 40 years of being involved with pest management I have always appreciated the value of the relationship with an engaged, active customer partner,” he says.

Future steps

There are many hurdles to what might be considered best practices for different food handling facilities, says Waggoner.

“Misinformation, misidentification, commitment and poor execution are among the top. Even our best practices are evolving with the speed of information flow into the support system. Artificial Intelligence in the pest control industry will have a major impact on how our monitoring and prevention should be done and when it should be done to minimize risk ahead of peak seasons that are relative to your industry and geographic location,” he posits.

Remote monitoring systems should replace some of the basic pest monitoring functions and aid in data collection, awareness, analysis, responsiveness and transparency, Waggoner says.

“We are definitely in the midst of a revolution right now and we are continuously working on sculpting that future of industry best practices. Trap checking is not pest management. We are training our technicians to think differently about their purpose within the system. Our value is not in checking the empty device and repeatedly reporting on little to no findings. It’s in the bigger picture of prevention and risk assessment system. Begin small enough to try and fail, yet big enough to scale up and see great results is the spot to be in, and I really think we are positioned well to help guide the next set of best practices for any industry.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!