Narrowing the list of suspects—Linking metal contamination in food to the production line

How do food manufacturers ensure what we eat is safe? As demands on production grow and food processing becomes more industrialized, quality control for food safety is increasingly critical.

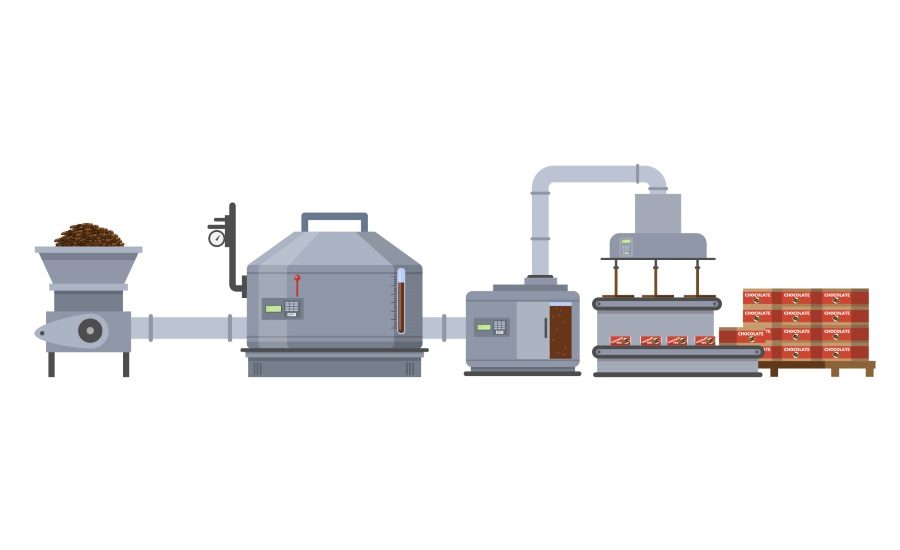

Efforts to increase productivity have introduced more automated and high-speed processing machinery into food production lines. When a food item is being processed, it passes through several machines, sieves, conveyer belts, drums, and tanks. Most of these machinery components are made of metal alloys, and each of these components that the food item encounters can increase the risk of foreign metal contamination.

Foreign metal contamination, a hazard inherent to industrial food processing

Over time, the metal components of processing machines can break down through various wear mechanisms, including abrasion, adhesion, surface and subsurface fatigue, or corrosion. When this happens, small shards of metal can end up in the food product. If this foreign material goes undetected, it has the potential to cause serious injury to consumers.

Chocolate, for example, undergoes many processing steps before the candy arrives on store shelves

To prevent physical hazards for consumers and to avoid a product recall, manufacturers use metal detection X-ray machines (similar to airport luggage scanners), which scan the food for small bits of metal. When these shards are detected, the next step is to figure out which part of the production line they are coming from. On a lengthy production line, a little bit of metal could come from many different places, so pinpointing the location is a significant challenge.

XRF analyzers help ID the culprit on the production line

Identifying the source of the metal fragment is a two-step process. First, the metal pieces are analyzed to determine their elemental composition. X-ray fluorescence (XRF) analyzers are effective at identifying the alloy grade of even small pieces of metal. Below, a small piece of metal is shown wrapped in a thin Prolene film so that it can be tested using an XRF analyzer.

In a few seconds, an XRF analyzer can analyze the metal shard’s chemistry and match it to a specific alloy grade—for example, stainless steel grade 316 (SS 316)—in its integrated alloy grade library.

The second step of the process involves matching the identified alloy grade of the fragment to metal components on the production line. This can be accomplished efficiently using one of the analyzer’s built-in functions. Manufacturers can create a customized library on the analyzer that links identified grades to specific components on their production lines. For example, if the drum of the micronization machine on their production line is composed of SS 316, the instrument can display “micronizer drum” when the alloy 316 is detected by the analyzer.

Effective preventative maintenance can help reduce metal contamination risk

This way, the manufacturer can identify the source of the metal shards and then investigate and mitigate the issue. This helps ensure that the production line is properly maintained and the final product is safe to eat for consumers.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!