Rapid Micro is Key to Rapid, Safe Food Production

A day in the life of today’s food production manager is not for the faint of heart. Underlying every operational food safety and quality assurance (QA) goal—from supporting HACCP programs to achieving faster screening of ingredients and raw materials, to reducing inventory holding times and achieving rapid intervention—is the need for speed.

“Everything in our production facility is about time,” says Shannon Shunk, quality assurance manager for Farmdale Creamery in San Bernardino, CA.

“If you can save time, you can make more product and sell more product every day.”

But that product also has to be safe when it leaves the food plant. Increased productivity, cost-effectiveness and reducing the risk of microbial contamination of foods is the trifecta of any food safety and QA professional’s mission, adds Shunk. Farmdale’s use of the BioSys technology, a rapid optical system for detection of microbial contaminants in foods, beverages, dairy, cosmetics, toiletries and nutraceuticals, is helping the creamery achieve its production goals more rapidly than ever before. “For a product like buttermilk with a 25-day shelf life, every day counts,” he says. “The BioSys rapid microbiological test delivers results in 10 to 12 hours instead of 24, which is a significant buffer. It’s extremely beneficial when you are working on such short timelines.”

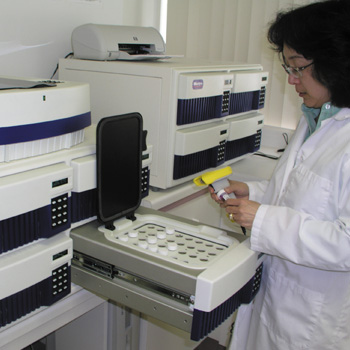

The patented system, developed by Ann Arbor, MI-based BioSys, Inc., is a computerized instrument with disposable vials for accurate and rapid microbiological testing. It is based on the detection of the metabolic processes of organisms by combining newly developed dye technologies with an optical sensor and provides screening results in as little as 7 hours. In addition to detecting microbial contamination, the BioSys system also detects the absence of pathogenic bacteria such as Listeria and the presence of other organisms, including coliforms, E. coli, Enterobacteriaceae, yeasts, molds and lactic acid bacteria.

Like Shunk, Kraft Foods’ Lori Ledenbach, associate principle scientist in the company’s research and development center in Glenview, IL, finds that time-savings in the form of speed-to-result has a significant impact on food plant productivity. She uses the BioSys technology for environmental and quality assurance testing, finding that with products such as salad dressings and processed cheese, the testing time for yeasts, molds and lactobacillus is reduced by two-thirds. “It’s a big benefit, especially for products that need to be held until testing is complete. We can reduce the hold time from five days to two while assuring that safe, high quality products are going out the door.”

Just as Accurate in Half the Time

The advent of rapid, automated microbiology testing has had a tremendous impact on the food industry, notes Dr. Joseph Odumeru, manager of regulatory services in the Laboratory Services Division of the University of Guelph, Ontario, Canada. From product development through the processing line and shipment, the time savings afforded by rapid microbial detection methods such as the BioSys are significant to the food company, which must keep its eye on producing verifiably safe foods of high quality. “You need a method to quickly determine whether there are pathogens or spoilage organisms in the food product and to verify the cleanliness of your environment, for example,” he says. “If you have to wait days for test results, the product may already be out the door. You don’t want those products to go out if they are adulterated.”

The BioSys system can rapidly detect indicator colonies of coliforms, E.coli and aerobic organisms, sometimes in a few hours, as compared with the 24- to 48-hour turnaround of traditional methods. “That’s important because 70% of the testing that the food industry conducts is for these three organisms,” Odumeru says.

But time savings is only valuable if the results are consistent and reliable. To prove the accuracy of the test, University of Guelph scientists validated the BioSys technology and found it to be “an excellent method for testing for indicator organisms,” says Odumeru. “It performs equally well with culture methods, with the additional benefit of delivering results in hours, not days.”

And because the BioSys delivers accurate total viable counts, it helps food processors make fast decisions as to whether a product passes or fails food safety and regulatory compliance mandates. Odumeru found that samples with high counts usually showed results in four to six hours, allowing technicians to respond more rapidly to product safety issues when they occurred.

Rapid microbiology technology is becoming a mainstay for research and development teams exploring the viability of new products, as well. Dr. Carl Catrenich, corporate microbiologist with Procter & Gamble, uses the BioSys system for preclinical efficiency and quality assurance tests of new products, which helps build in microbial reduction from the get-go. “It’s a very versatile piece of equipment,” he says, adding that the system can be used across the business, upstream and down. “If you can test a product more quickly and get it out the door, you can reduce inventory.”

Real-time results in a real-world processing environment is imperative, agrees Farmdale’s Shunk, whose background is in production, not microbiology. “What you need to know about microbiology to successfully use the BioSys is minimal,” he says. “This technology is the future.”

biosystesting.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!