Risk Analysis Drives Safety Testing for Dietary Supplement Maker

When Jon Cassista, Ph.D., was charged with establishing microbial quality control specifications for dietary supplement and natural foods manufacturer/distributor NOW Foods in Bloomingdale, IL, he initially thought that it would simply be a matter of NOW Foods adopting existing industry regulations and norms. The challenge, Cassista found, was that while the food and pharmaceutical industries often had numerical specifications, no similar specifications existed for manufacturers of vitamins, minerals, and herbs.

“My first task was to set up microbiological specifications for the hundreds of raw ingredients that go into our products,” says Cassista, currently Now Foods’ senior scientist, who oversees microbial safety testing for the company’s approximately 1,500 products.

The challenge Cassista and his staff faced was monumental. Commodity testing validations simply do not exist for most of the hundreds of obscure herbs and other raw ingredients plucked from every corner of the world that go into NOW Foods’ products. Furthermore, establishing the nearly countless commodity validations was well beyond the reach of Cassista and his small lab staff.

“We started by establishing testing priorities based on risk categories,” he says, noting that products such as organic natural foods (seeds, nuts, grains) that would be consumed in gram quantities with no further consumer processing presented a greater possible risk than herbal powders or extracts that are used in milligrams per capsule or tablet because the milligram amounts represent a thousand-fold dilution of the raw ingredient to the consumer.

“We also looked at who consumed our particular products,” he says. “Infants, the elderly and immune-compromised consumers obviously are at higher risk.”

In addition, Cassista considered the country of origin, methods of harvesting and processing, and history of microbial issues with the raw material to establish the appropriate category for tests. Cassista said he also factors a raw ingredient’s water activity into its risk assessment. Ingredients that arrive at NOW Foods clean and dry, and are kept clean and dry throughout production, pose less risk to support the growth of pathogens or spoilage organisms.

Quarantine Time Cut in Half

Based on the establishment of Cassista’s risk categories, NOW Foods’ in-house microbiology lab currently runs hundreds of samples per month to ensure the safety and quality of its products with respect to potential pathogens and spoilage. Like micro labs throughout the food industry, NOW Foods’ lab is tasked with many other responsibilities, such as testing the effectiveness of antimicrobial properties of many company products and monitoring the water and production environment.

To streamline the lab’s testing for potential pathogens and spoilage organisms, approximately two years ago NOW Foods purchased a Soleris optical microbial detection system (Neogen Corporation, Lansing, MI). The Soleris system rapidly detects microbes by monitoring the color changes produced by changing pH, and other reactions, generated by microbial growth. The automated system needs only a fraction of the time of the traditional methods that NOW Foods used, with significantly less technician hands-on time.

Currently, approximately 65 percent of the samples run in the micro lab are incoming raw ingredients. The other 35 percent are finished goods, stability samples and new vendor items. He said the lab regularly tests product samples for total viable count (TVC), E. coli and Enterobacteriaceae using the automated test system.

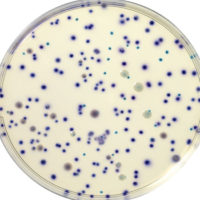

In addition to the optical-based system, NOW Foods also uses the ISO-GRID membrane filtration microbial detection system from Neogen to test samples for yeasts and mold. “We used to perform the standard five- to seven-day yeast and mold test, but we’ve found that the results using ISO-GRID track very nicely with the standard test,” Cassista says. “We’ve run the ISO-GRID test for 48 and 72 hours, compared the two, and found that the 48-hour count is useful for us. Getting product out of quar-antine in two to three days instead of five to seven makes a significant difference.”

“The new system has helped us cut down our quarantine time from five to six days to approximately three days for micro testing,” said Cassista. “That is a significant difference for us. The sooner we can clear a product in our micro lab, the sooner we can ship it to our customers, so testing time is very important to us. For our customers, it translates into more products in stock, very few back orders and great on-time delivery.”

Neogen Corporation’s Jason Lilly, Ph.D., says the challenges faced at NOW Foods’ micro testing lab are unique in one sense, but quite common in another. “We rarely encounter the vast and wide-ranging sample types that Dr. Cassista has seen move through his company’s lab,” Lilly says, “but, almost without exception throughout the nutraceutical and food industries, in-house testing labs are being required to run more samples more quickly—and frequently with smaller staffs. The result has been that testing labs have moved away from traditional methods and are seeking the time- and labor-saving benefits of the newest testing technologies.”

neogen.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!