Bürkert’s Updates Type 8650 AirLINE Valve Island, Optimized for Use in Hazardous Areas

Credit: Bürkert

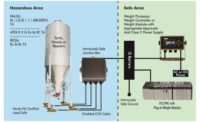

The use of pneumatic process control systems offers many advantages food and beverage manufacturers, especially in hazardous areas. Bürkert’s AirLINE range of valve islands has been developed and proven in the field for many years, and the latest update extends the functionality in the most challenging environments.

The new Type 8650 has an integrated pressure sensor and a filter in the air supply to ensure optimum performance. The solution also has an extended temperature range, and IECEx/ATEX approvals have been updated to the latest specifications. In addition, new functions have been directly integrated onto the valve island, which controls process equipment while located in zones 1/21.

The Type 8650 was originally developed with the cooperation of Siemens, and the partnership enabled complete integration with the SIMATIC ET 200iSP. The Type 8650 is the only valve island featuring hardware and software that is fully integrated with the Siemens IO system. This includes the diagnostics, which ensures that any fault signals are directly integrated with the PCS7 process control system.

The external valve shutdown function enables the pneumatic feed to the valve island to be closed off while the communications remain operational with the rest of the network. At the same time, air inside the valve island will be exhausted to atmosphere, preventing any further process valve actuation. This ensures that any feedback relating to the shutoff, such as the final position of a valve, is relayed to the central processor.

Bürkert: www.burkert.co.uk

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!