Operations

Legacy snack and bakery facilities pose their fair share of sanitation challenges

Read More

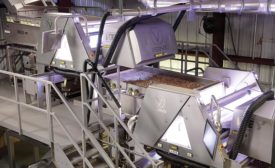

Inspection and detection equipment reach new levels of flexibility for peak food safety

X-ray, metal detection, checkweighing and vision systems help processors ensure food safety

January 22, 2019

Finding the right HPP solution

Operation size, extensive testing and understanding business capabilities are crucial steps

January 11, 2019

Never miss the latest news and trends driving the food safety industry

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing